Basic Info.

Connection Type

Flange

Length

as Client′s Requirements

Size

DN80~2600mm

Certification

ASTM DIN GB

Specifications

as Client′s Requirements

Color

Black or as Customers′ Request

Pressure

Pn10, Pn16, Pn25, Pn40

Application

Water Supply Project, Drainage, Sewage, Irrigation

Packing

Standard Sea-Worthy Export Packing

Delivery Time

7-15 Days

Payment Terms

Tt or L/C

Transport Package

Standard Seaworthy Export Packing

Specification

Customized Size

Trademark

Huabei

Origin

Shandong, China

Production Capacity

1000 Tons Per Month

Product Description

Product Description

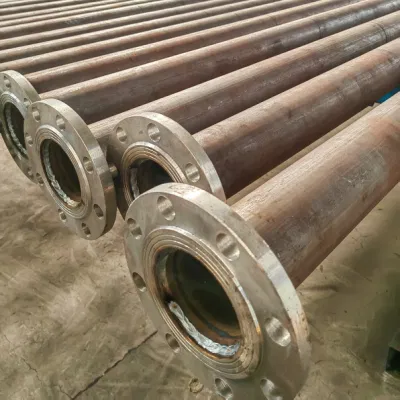

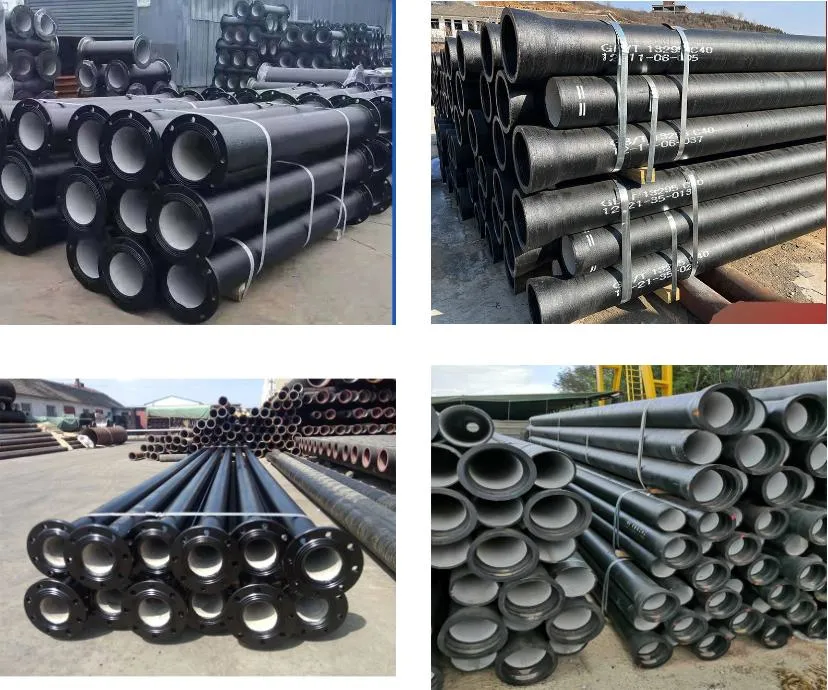

Double Flanged Ductile Cast Iron Pipe is the first choice of pipe for the municipal water supply project with advantages of convenient installation, good seismic performance and corrosion resistance. The range of sizes of our Ductile Iron pipes are from DN80mm to DN1800.

Double Flanged Ductile Iron Pipes are layed in the way of mechanical flanged joint in the project site.

Double Flanged Ductile Iron Pipes are layed in the way of mechanical flanged joint in the project site.

Advantages of Ductile Iron Pipe

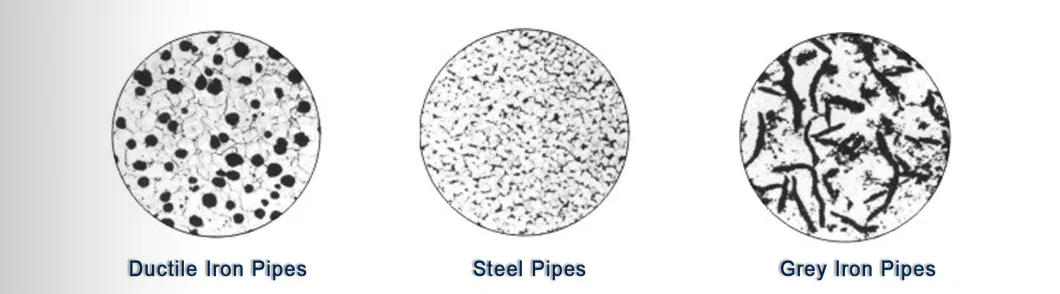

* Ductile Iron pipe have better Mechanical Properties .

( Note: Microstructure comparision between Ductile Iron Pipe, Steel Pipe and Grey Iron Pipe )

( Note: Microstructure comparision between Ductile Iron Pipe, Steel Pipe and Grey Iron Pipe )* Ductile Iron Pipe have better mechanical propeties

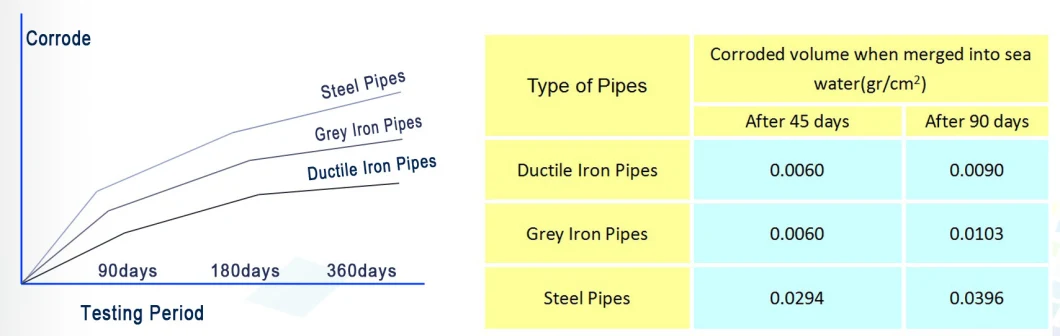

* Ductile Iron Pipe have Higher Corrosion Resistance

Works test pressure

| Nominal Size DN | Hydrostatic works test pressure bar |

| 80-300 | 50 |

| 350-600 | 40 |

| 700-1000 | 32 |

| 1200-2000 | 25 |

| 2200-2600 | 18 |

Thickness of cement lining

| DN | Nominal value | Tolerance 1) | Maximum crack width and radial displacement |

| 80-300 | 4 | -1.5 | 0.4 |

| 350-600 | 5 | -2 | 0.5 |

| 700-1200 | 6 | -2.5 | 0.6 |

| 1400-2000 | 9 | -3 | 0.8 |

| 1)A negative tolerance only is given. Note: Pipe end may have a chamfer of maximum length 50 mm. | |||

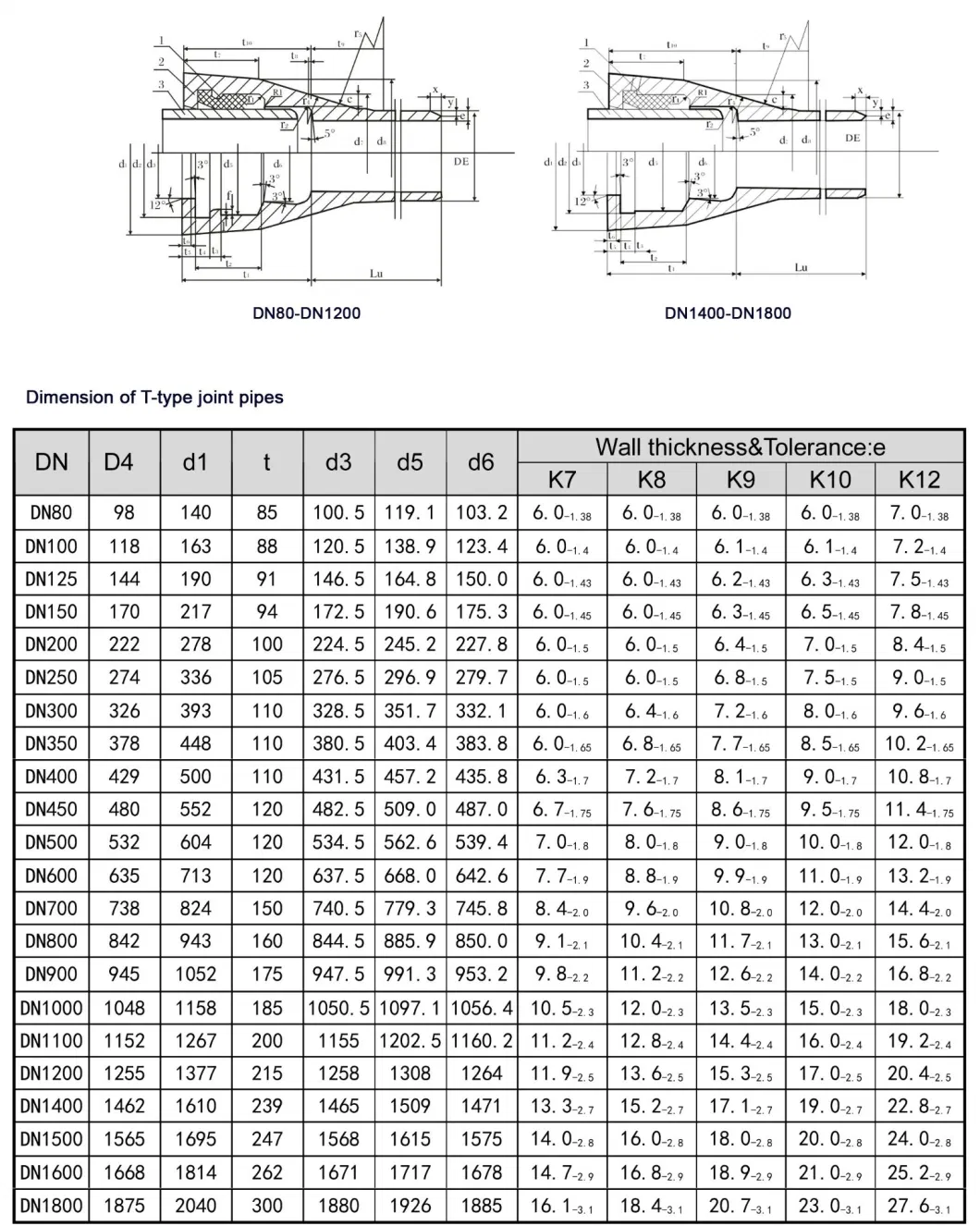

Technical Data of K Type Joint Ductile Iron Pipe :

Technical Data of K Type Joint Ductile Iron Pipe :

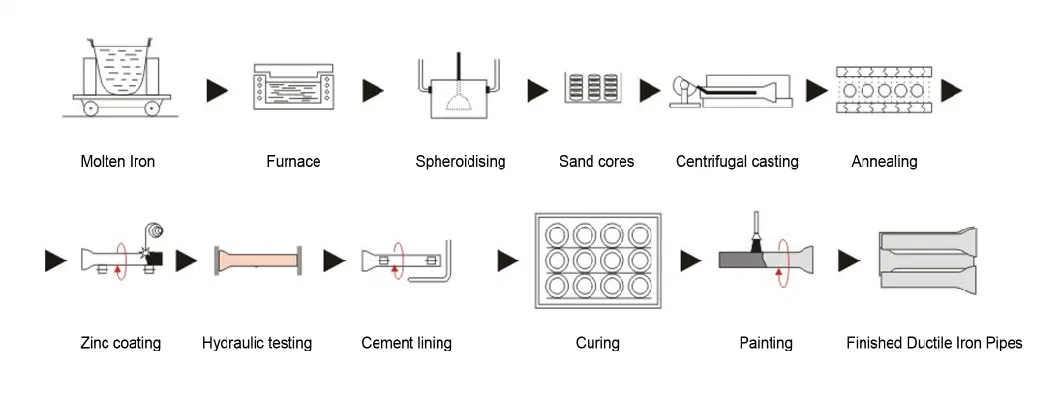

Production Process

Mechanical Properties of Ductile Iron Pipe :

Mechanical Properties of Ductile Iron Pipe :

Hydrostatic Pressure Test of Ductile Iron Pipe :

| DN(mm) | Minimum Test Pressure (Bar) | Duration Time | ||

| ISO2531-1998 | ISO2531-2009 | |||

| K<9 | K≥9 | Preferred pressure classes | S | |

| ≤300 | 0.5(K+1)2 | 50 | 40 | 10S |

| 350-600 | 0.5K2 | 40 | 30 | 10S |

| 700-1000 | 0.5(K-1)2 | 32 | 25 | 10S |

| 1200-2000 | 0.5(K-2)2 | 25 | 25 | 10S |

| 2200-2600 | 0.5(K-3)2 | 18 | 25 | 10S |

Production Inspection

Packing & Shipping

Application

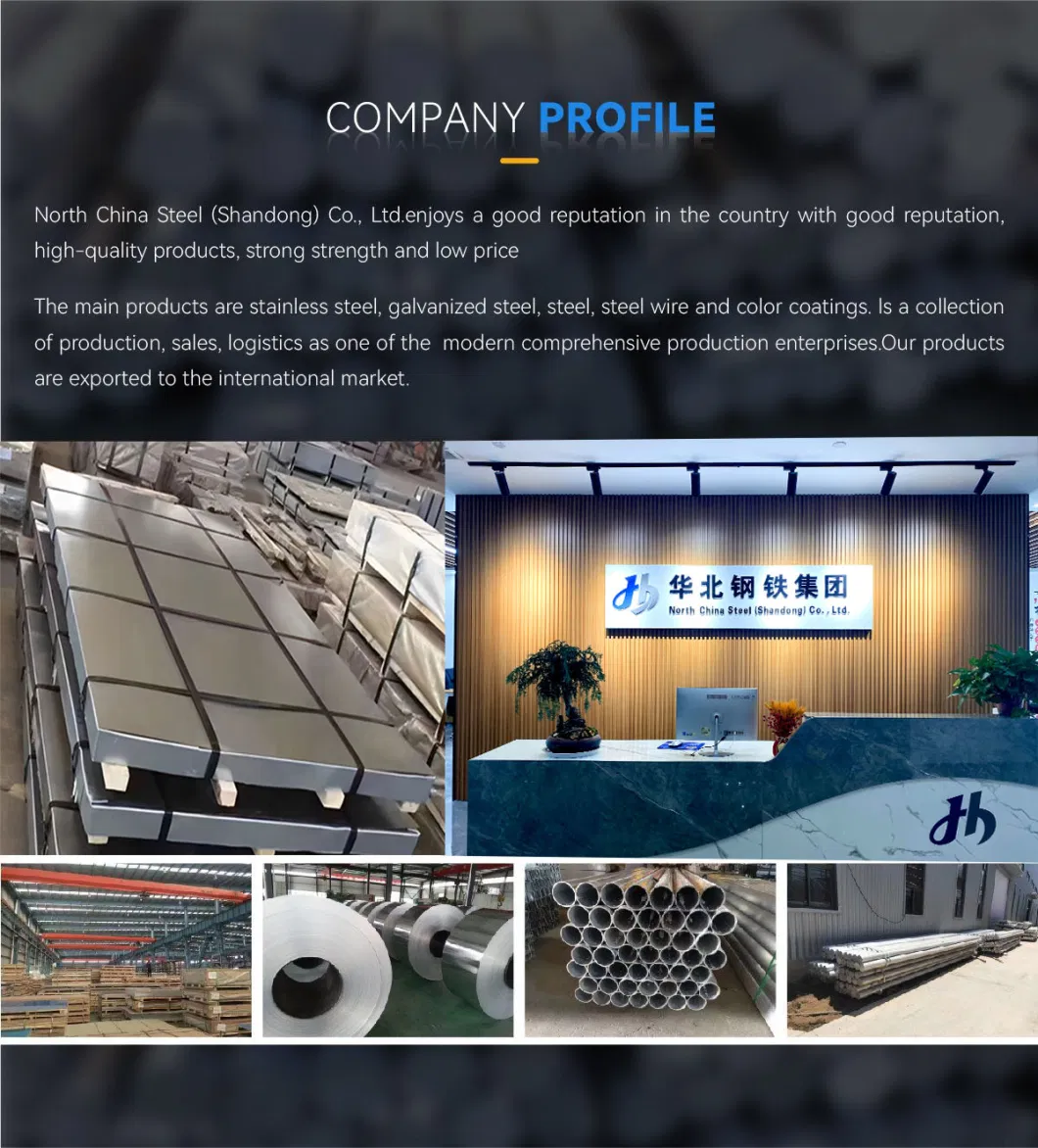

Company Profile

Company Profile

Our customer

Hot Sales

Hot Sales Why Choose us

Why Choose us

FAQ

FAQ Q1. How long can make delivery?

A1:For stock material,the delivery time is just 7-15 working days.

And for customized product,it will takes 25-35 working days based on different size and quantity.

Q2. Can you accept customize?

Yes. It can be customized as per the customers' request.

Q3. Are you trading company or manufacturer ?

We are professional manufacturer for steel products, and our company also is a very professional a trade company for steel

products.we can also provide a wide range of steel products.

Q4.What are the advantages of your company ?

We have many professionals, sales personnel, more competitive prices and best after-dales service than other steel companies.

Q5: Can you supply the sample? Does it free or not?

For partial materials,we can supply the sample but it is not free.

If you want to know more details,please contact our sales online.

Q6:What's the terms of payment?

A3:We can accept T/T & LC at sight.

Q7.How can we get your price ?

We need below information to quote for you:

1. Product Name

2. Standard

3. Material Grade (Chemical Composition)

4. Dimension

5. Quantity

6. The Drawing for Special Parts