- Overview

- FAQ

Basic Info.

Packaging & Delivery

Product Description

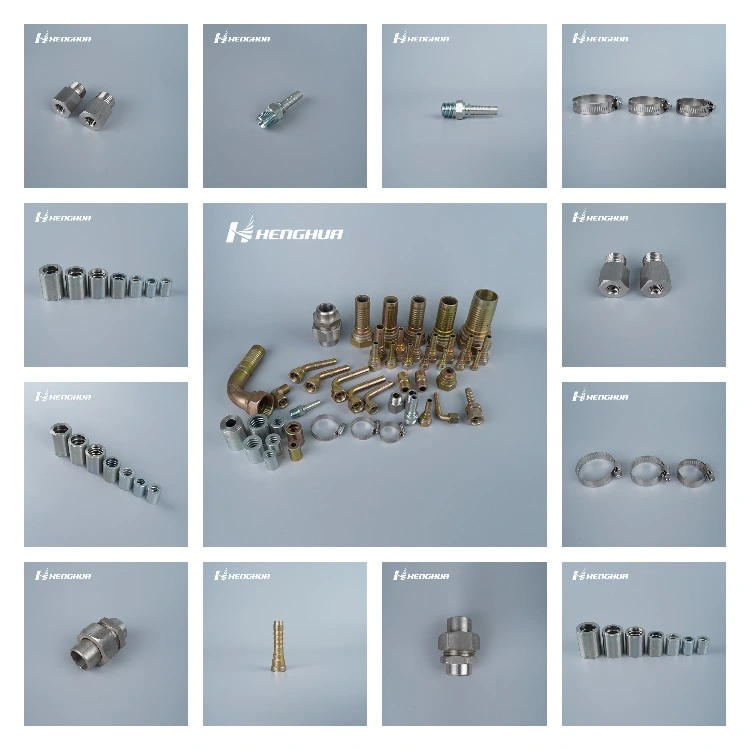

Henghua Hydraulic offers a large range of hydraulic hose & fittings suitable for use on various applications across multiple industries.

Our hydraulic hose range includes 1SC, 2SC, 100 R1-R17, 4SP, 4SH ,1SN,2SN,1-3TE& suction & delivery hose, along with compatible hose inserts and ferrules.

If you're not sure what type of hose you should be using for your application, please get in touch and we will provide you with the correct hose for the job!

We don't only supply loose hose and hose fittings we can also make bespoke hose assemblies to your given specification, get in touch with our friendly sales team to discuss your hose assembly needs today.

SAE 100 R1 steel wire reinforced hydraulic hose is suitable for hydraulic lines and usual industrial systems. It can bear higher working pressure than other rubber hoses thanks to its high tensile braided steel wire reinforcement. It is composed of three parts: tube, reinforcement and cover. The tube is made from oil resistant synthetic rubber, making the hose have excellent performance in delivering oils. The reinforcement is made from one layer of high tensile braided steel wire, making the hose have outstanding high pressure resistance. The cover is made from high quality synthetic rubber, making the hose resistant to abrasion, corrosion, weather, ozone, aging, sunlight and cut. Therefore, it has longer service life.

Details of SAE 100 R1 steel wire reinforced hydraulic hose:

- Structure: it is composed of three parts: tube, reinforcement and cover.

- Tube: high quality oil resistant synthetic rubber, making the hose work well in delivering oils.

- Reinforcement: one layer of high tensile braided steel wire, making the hose work well in high pressure environment.

- Cover: high quality synthetic rubber, making the hose resistant to abrasion, corrosion, weather, ozone, aging and cut.

- Working temperature: -40 °C to +100 °C.

| Hose code | Size | Dash size | ID | WD | OD | |||||

| A | AT | |||||||||

| mm | inch | min | max | min | max | min | max | max | ||

| SAE100R1-01 | 5 | 3/16 | -3 | 4.6 | 5.4 | 8.9 | 10.1 | 11.9 | 13.5 | 12.5 |

| SAE100R1-02 | 6.3 | 1/4 | -4 | 6.2 | 7 | 10.6 | 11.7 | 15.1 | 16.7 | 14.1 |

| SAE100R1-03 | 8 | 5/16 | -5 | 7.7 | 8.5 | 12.1 | 13.3 | 16.7 | 18.3 | 15.7 |

| SAE100R1-04 | 10 | 3/8 | -6 | 9.3 | 10.1 | 14.5 | 15.7 | 19 | 20.6 | 18.1 |

| SAE100R1-05 | 12.5 | 1/2 | -8 | 12.3 | 13.5 | 17.5 | 19 | 22.2 | 23.8 | 21.5 |

| SAE100R1-06 | 16 | 5/8 | -10 | 15.5 | 16.7 | 20.6 | 22.2 | 25.4 | 27 | 24.7 |

| SAE100R1-07 | 19 | 3/4 | -12 | 18.6 | 19.8 | 24.6 | 26.2 | 29.4 | 31 | 28.6 |

| SAE100R1-08 | 25 | 1 | -16 | 25 | 26.4 | 32.5 | 34.1 | 36.9 | 39.3 | 36.6 |

| SAE100R1-09 | 31.5 | 1-1/4 | -20 | 31.4 | 33 | 39.3 | 41.7 | 44.4 | 47.6 | 44.8 |

| SAE100R1-10 | 38 | 1-1/2 | -24 | 37.7 | 39.3 | 45.6 | 48 | 50.8 | 54 | 52 |

| SAE100R1-11 | 51 | 2 | -32 | 50.4 | 52 | 58.7 | 61.9 | 65.1 | 68.3 | 65.9 |

| Hose code | Working pressure | Proof pressure | Min burst pressure | Min bending radius | Weight | |||

| MPa | psi | MPa | psi | MPa | psi | mm | kg/m | |

| SAE100R1-01 | 21 | 3045 | 42 | 6090 | 84 | 12810 | 90 | 0.2 |

| SAE100R1-02 | 19.2 | 2780 | 38.5 | 5580 | 77 | 11165 | 100 | 0.25 |

| SAE100R1-03 | 17.5 | 2540 | 35 | 5075 | 70 | 10150 | 115 | 0.31 |

| SAE100R1-04 | 15.7 | 2280 | 31.5 | 4570 | 63 | 9135 | 125 | 0.36 |

| SAE100R1-05 | 14 | 2030 | 28 | 4060 | 56 | 8120 | 180 | 0.45 |

| SAE100R1-06 | 10.5 | 1520 | 21 | 3045 | 42 | 6090 | 205 | 0.52 |

| SAE100R1-07 | 8.7 | 1260 | 17.5 | 2540 | 35 | 5075 | 240 | 0.65 |

| SAE100R1-08 | 7 | 1015 | 14 | 2030 | 28 | 4060 | 300 | 0.91 |

| SAE100R1-09 | 4.3 | 620 | 8.7 | 1260 | 17.5 | 2540 | 420 | 1.3 |

| SAE100R1-10 | 3.5 | 510 | 7 | 1015 | 14 | 2030 | 500 | 1.7 |

| SAE100R1-11 | 2.6 | 380 | 5.2 | 750 | 10.5 | 1520 | 630 | 2 |

| Hydraulic Hose | Reinforcement | Product Name |

| One steel wire braided | SAE R1AT/DIN 1SN,SAE R1AT/DIN 1ST,DIN 1SNK,DIN/EN 1SN WG,DIN 1SC,SAE R5,SAE 100R17 | |

| Two steel wire braided | SAE R2AT/DIN 2SN,SAE R2AT/DIN 2ST,DIN 2SNK,DIN 2SC | |

| One/two wire braided | SAE R16 | |

| Four steel wire spiral | SAE R9AT,SAE R10,SAE R12,DIN 4SP,DIN 4SH | |

| High flexibility nylon or thermoplastic | SAE R7,SAE R8 | |

| Industrial Hose | Steam hose,Water/Air hose,Fuel/Oil hose,Washer hose | |

| Product Name | Chief Introduction |

| Air Hose | High strength synthetic yarn reinforced |

| Water Hose | High strength synthetic yarn reinforced |

| Oil Hose | Single/double synthetic yarn braided or spiraled |

| Welding Hose | High strength synthetic cord reinforced |

| Gas Hose(LPG Hose) | High tensile synthetic yarn braided or spiraled |

| Heat Resistent Hose | 1 or 2 piles of fiber braid reinforcement |

| Air Condition Hose | Strengthen lining is weaving fiber |

1.What hose do you provide?

HENGHUA pipeindustry company offer hundreds of products. Main hose products:

high pressure steel wire braided hose,

high pressure steel wire spiral rubber hose,

steel wire winding hose,

flame retardant,resistance to high temperature and high pressure drilling hose

assembly,marine high pressure oil hose,

expansion pipe,

metal hose,

rollers,

rubber seals,etc

2.What are the product applications?

Mining, hydraulic support, hydraulic system, emulsification pump, construction machinery, coal mine underground water delivery, feng shui working face, water delivery, oil transportation, sand pumping, mud discharge, suction dust, exhaust gas, ash, engine gas pumping, Gas drainage / gas discharge / warm air duct

3.What are your advantages?

High quality, complete specifications, stock in stock. company has passed ISO9001:2015 international quality management system certification, ISO14001:2015 environment management system certification. HOSAS18001:2007 certification of safety management system certification,mining products safety sign,etc.

Products are sold well all over the country, and exported to India,British,Russia,Turkey,Germany, the United States and other countries,favored by the users.