- Overview

- Company Profile

- Product Description

- Product Parameters

- Our Advantages

- Installation Instructions

- Cases

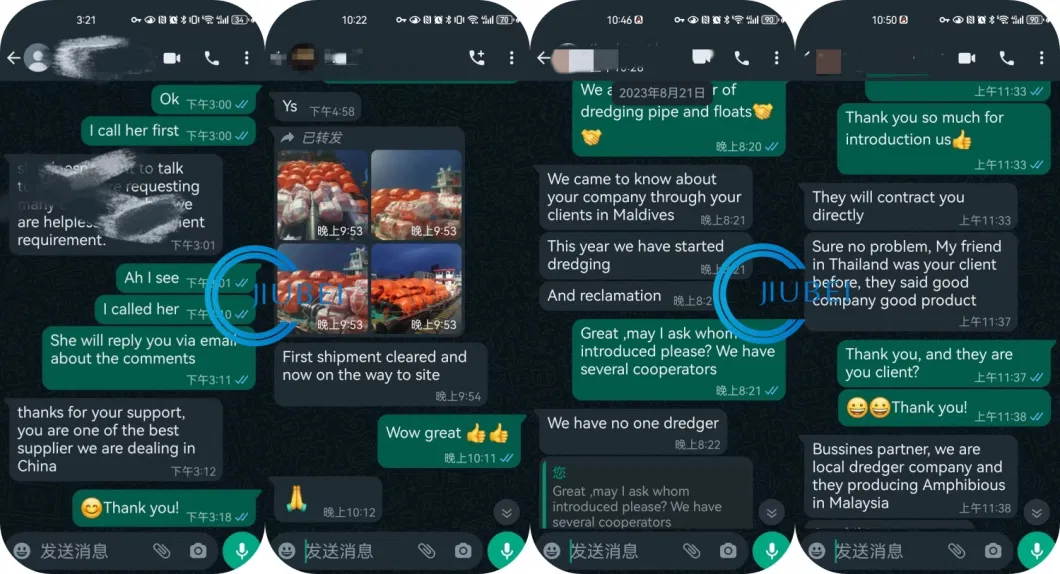

- Feedback

Basic Info.

Product Description

Our Benefits:

1, We have been worked in this field for more than 10 years, and have very rich workshop sources, familiar with each workshop's advantage, will help you find the most suitable product.

2, We have inspection team, since we get your order, our inspection people will follow on your goods' production process and quality,for production process, each day we have production status update; for inspection, we have raw material inspection, first goods inspection, random inspection and ex-works inspection as well as other tests for the exact goods.

3, We have professional and experienced export team to handle the export issues.

Our Company promises: Qualified goods,reasonable price, delivery in time, and satisfied after-sales service!

HDPE dredging pipe introduction

The inner wall of the PE water supply pipe is smooth and does not change with the time of use. The friction resistance is small, which saves energy. The pressure loss is about 30% smaller than that of the steel pipe. A smaller diameter than the steel pipe can be selected. Good hygienic performance, no additives, no possibility of polluting drinking water, ISO standard graded polyethylene material is 0 (lower grade), mold-free material, compared with other commonly used plastic materials, polyethylene's mold resistance It is much higher and does not accumulate scale after long-term use.

PE pipe is suitable for general purpose pressure water delivery and drinking water transportation with temperature not exceeding 40ºC and nominal pressure below 1.6MPa. Mainly include municipal buried water supply, construction (drain) water, farmland irrigation, water feature engineering, fine sand/slurry dredging etc.

The flanged HDPE dredging pipe is easy to be connected, which reduced the swings caused by the waves and makes the medium smoother in the pipe.

The HDPE dredging pipes are used for drainage, water-logging, dredging and sand discharging of port.

| Item | Test Method | Unit | UHMWPE Pipe | HDPE Pipe | PA66 Pipe | PVC Pipe | Steel Pipe |

| Viscosity-average Molecular Weight | ISO1628-3 | 104g/mol | 500-1050 | <50 | - | - | - |

| Approx Melting Temperature | ISO11357.3 | ºC | 136 | 129 | 255 | 160 | 1410 |

| Water Absorption | ISO62-1999 | % | <0.01 | <0.01 | 3.8 | 0.5 | - |

| Coefficient of Linear Thermal Expansion | ISO11359-2 | 10-4/ºC | 1.5 | 1.2 | 0.8 | 0.9 | 0.17 |

| Density | ISO1183-1-2004 | g/cm3 | 0.935-0.945 | >0.940 | 1.13-1.15 | 1.4 | 7.8 |

| (0.45MPa) Heat Deformation Temp at 0.45Mpa | ISO75 | ºC | 85 | 71 | 182-224 | ≥54 | 1230 |

| Tensile Strength | ISO527 | MPa | >39 | <25 | 61 | 40 | 550 |

| Yield Strength | ISO527 | MPa | ≥22 | 20 | - | 19 | ≥245 |

| Tensile Elongation | ISO527 | % | ≥250 | ≥350 | 60-300 | 60 | 20 |

| Gap Beam Impact Strength | ISO179 | KJ/m2 | No fracture | <27 | 5.9-10.8 | <10 | No fracture |

| Rockwell Hardness | ISO2039-2 | R | 40 | 33 | 85-120 | 118 | 45(C) |

| Friction Coefficient | ISO8295 | - | 0.05-0.11 | 0.28 | 0.37 | 0.4-0.6 | 0.58 |

| Mortar WearIndex | - | - | 1 | 10 | 5 | 10 | 7 |

| Scaling | - | - | NoScaling | Slight | Slight | Slight | Heavy |

| Corrosion Resistance | - | - | Excellent | Common | Common | Common | Bad |

HDPE Pipe dimensions

National standard nominal wall thickness of HDPE pipe | ||||||||

| GB/T13663.2.2018 | Standard Dimension | |||||||

| SDR41 | SDR33 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 | |

| PE 80 Nominal Working Pressure | ||||||||

| 0.32 | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.25 | 1,6 | |

| PE100 Nominal Working Pressure | ||||||||

| 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.25 | 1.6 | 2.0 | |

| DN(mm) | Thickness(mm) | Thickness(mm) | Thickness(mm) | Thickness(mm) | Thickness(mm) | Thickness(mm) | Thickness(mm) | Thickness(mm) |

| 16 | 2.3 | |||||||

| 20 | 2.3 | 2.3 | ||||||

| 25 | 2.3 | 2.4 | 3.0 | 3.6 | ||||

| 32 | 2.4 | 3.0 | 3.7 | 4.5 | ||||

| 40 | 2.3 | 3.0 | 3.7 | 4.6 | 5.6 | |||

| 50 | 2.3 | 2.4 | 3.6 | 4.7 | 5.8 | 7.1 | ||

| 63 | 2.5 | 3.0 | 4.3 | 5.6 | 6.8 | 8.4 | ||

| 75 | 2.9 | 3.6 | 5.3 | 6.7 | 8.2 | 10.1 | ||

| 90 | 3.5 | 4.3 | 6.0 | 8.1 | 10.0 | 12.3 | ||

| 110 | 4.2 | 5.3 | 6.7 | 9.2 | 11.4 | 14.0 | ||

| 125 | 4.8 | 6.0 | 7.7 | 10.3 | 12.7 | 15.7 | ||

| 140 | 5.4 | 6.7 | 8.6 | 11.8 | 14.6 | 17.9 | ||

| 160 | 6.2 | 7.7 | 9.6 | 13.3 | 16.4 | 20.1 | ||

| 180 | 6.9 | 8.6 | 10.8 | 14.7 | 18.2 | 22.4 | ||

| 200 | 7.7 | 9.6 | 11.9 | 16.6 | 20.5 | 25.2 | ||

| 225 | 8.6 | 10.8 | 13.4 | 18.4 | 22.7 | 27.9 | ||

| 250 | 9.6 | 11.9 | 15.0 | 20.6 | 25.4 | 31.3 | ||

| 280 | 10.7 | 13.4 | 16.9 | 23.2 | 28.6 | 35.2 | ||

| 315 | 7.7 | 9.7 | 12.1 | 15.0 | 19.1 | 26.1 | 32.2 | 39.7 |

| 355 | 8.7 | 10.9 | 13.6 | 16.9 | 21.5 | 29.4 | 36.3 | 44.7 |

| 400 | 9.8 | 12.3 | 15.3 | 19.1 | 23.9 | 33.1 | 40.9 | 50.3 |

| 450 | 11.0 | 13.8 | 17.2 | 21.5 | 26.7 | 36.8 | 45.4 | 55.8 |

| 500 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 41.2 | 50.8 | 62.5 |

| 560 | 13.7 | 17.2 | 21.4 | 26.7 | 37.4 | 46.3 | 57.2 | 70.3 |

| 630 | 15.4 | 19.3 | 24.1 | 30.0 | 42.1 | 52.2 | 64.5 | 79.3 |

| 710 | 17.4 | 21.8 | 27.2 | 33.9 | 47.4 | 58.8 | 72.6 | 89.3 |

| 800 | 19.6 | 24.5 | 30.6 | 38.1 | 53.3 | 66.2 | 81.7 | |

| 900 | 22.0 | 27.6 | 34.4 | 42.9 | 59.3 | 72.5 | 90.2 | |

| 1000 | 24.5 | 30.6 | 38.2 | 47.7 | 67.9 | 88.2 | ||

| 1200 | 29.4 | 36.7 | 45.9 | 57.2 | 82.4 | 102.9 | ||

| 1400 | 34.3 | 42.9 | 53.5 | 66.7 | 94.1 | 117.6 | ||

| 1600 | 39.2 | 49.0 | 61.2 | 76.2 | 105.9 | |||

| 1800 | 43.8 | 54.5 | 69.1 | 85.7 | 117.6 | |||

| 2000 | 48.8 | 60.6 | 76.9 | 95.2 | ||||

| 2250 | 55.0 | 70.0 | 86.0 | 107.2 | ||||

| 2500 | 61.2 | 77.7 | 95.6 | 119.1 | ||||

· High impact strength

· Extremely light weight and hence easy to handle

· High flexibility

· High abrasion resistance

· Excellent water hammer characteristic helps, sustaining surges

· Excellent flow characteristics leading to significant energysavings

·Shifting soils -no breakage

· Earthquake resistance

· No infiltration, helps maintaining the quality of fluids beingconveyed

· No trenches needed, resulting into easy and economicalinstallation

· High UV resistance to scaling and biological build up

·Allows fusion to eliminate leakages

Technical Parameters of HDPE pipeline

| No. | Item | Requirements | |

| 1 | Elongation at break% | ≥350 | |

| 2 | Longitudinal reversion(100ºC), % | ≤3 | |

| 3 | Oxidation induction time(200ºC)min | ≥20 | |

| 4 | Weather resistance after the pipe has accepted the aging energy which equal to or more than 3.5GJ/m2≤ | 80ºC static hydraulic strength(165h) | Non breakage and leakage |

| Percentage of breaking-elongation,% | ≥350 | ||

| Oxidation induction time(200ºC)min | ≥10 | ||

Installation of 11.8m length flanged high wear resistant HDPE pipeline applied for sand/slurry/mine discharging

Cases of 11.8m length flanged high wear resistant UHMWPE pipeline applied for sand/slurry/mine discharging