- Overview

- Product Description

- Detailed Photos

- Applications

- Advantages

- Characteristics

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Product Description

A Steel wire wrapped skeleton reinforced polyethylene composite pipe(DN50-630mm)

B Flexible composite high-pressure conveying pipe(DN50-150mm)

| Steel wire wrapped skeleton reinforced polyethylene composite pipe: Polyethylene resin (polyethylene HDPE, heat-resistant polyethylene PE-RT, etc.) is used as the base material, the steel mesh skeleton is the reinforcement, and the extruded steel skeleton reinforced polyethylene composite pipe is used.(Steel wire wrapped skeleton reinforced polyethylene composite pipe) | Flexible composite high-pressure conveying pipe: It uses polyethylene resin (polyethylene HDPE, heat-resistant polyethylene PE-RT, cross-linked polyethylene, polyvinylidene fluoride) as the base material, and polyester, aramid, steel wire rope, ultra-high molecular weight polyethylene filament, etc. as reinforcements. Extruded flexible composite high-pressure conveying pipe. |

The standards implemented are the oil and gas industry standards of the People's Republic of China: SY/T 6662.1-2012 Non-metallic composite pipes for the oil and gas industry Part 1: Steel skeleton reinforced polyethylene composite pipes(Steel mesh skeleton reinforced polyethylene composite pipe) SY/T 6662.2-2020 Non-metallic composite pipes for the oil and gas industry Part 2: Flexible composite high-pressure conveying pipes

It is mainly composed of five layers: the inner and outer layers are made of thermoplastic plastic, made of HDPE, PERT, etc., and the middle layer is a steel wire reinforcement layer that has been coated with rubber. A layer of bonding resin is added to both sides of the steel wire reinforcement layer to make the reinforcement layer and the inner and outer layers Bonded into one.

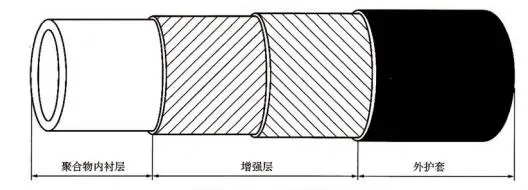

It is mainly composed of three layers: the inner thermoplastic pipe is made of thermoplastics such as HDPE, PERT, PA, and PVDF. The middle layer is a reinforced material layer wound at a specific angle. The materials include aramid fiber, polyester fiber, glass fiber, etc. The outer layer is a protective layer, usually HDPE with anti-aging and anti-UV added.

Nominal pressure:

The maximum working pressure of composite pipes and fittings when transporting media at 20°C. The unit is megapascal (Mpa).

Average outer diameter:

Use the circumference method to measure the value of the circumference of the outer wall of the composite pipe divided by 3.142 (pi). The result is rounded to 0.1mm. If the second digit after the decimal point is greater than zero, it is rounded up to one digit. The unit is millimeters (mm).

Nominal outer diameter:

The number identifying the size represents the outer diameter of the composite pipe. Use an integer and the unit is millimeters (mm).

Polyethylene compounding ingredients:

Pellets made from polyethylene base resin with necessary antioxidants, UV stabilizers and pigments.

1. Preservative

2. High pressure

3. Heat resistant and preservation

4. Strong conveying capacity

5. Good flexibility

6. Convenient construction

7. Few connectors

8. High cost performance

9. Good hygienic performance

10. Long lasting

Composite pipes should be laid flat or rolled up, and the stacking height should not exceed 3.0m. Composite pipe reels are not permitted to be suspended from a fixture.

When transporting, lift the grab strips on the packaging at the same time to keep the composite pipe basically straight. When using machinery, lifting rings or wire ropes to lift composite pipes, it is necessary to prevent damage to the outer cladding of the composite pipes.

During transportation, avoid sunlight, rain and snow; prevent contact with some substances that can damage the composite pipe, and keep it at least 1m away from heat sources.

We are a professional manufacturer of all types of flexible hoses and machinery, such as corrugated metal hoses, flexible metal conduit, composite hoses, Steel Skeleton Plastic Pipes, square lock and interlock hoses/conduits, PTFE hoses, etc with more than 25 years of experience. Our factory has a modern factory, advanced manufacturing processing, testing equipment, and a strong technical force.

Q1. Who is COMFLEX?

COMFLEX is a reliable manufacturer and exporter of RTP composite pipe in China for more than 30 years in the market.

Q2. What are you offering?

We offer steel wire wrapped skeleton reinforced RTP composite pipe and flexible composite high-pressure conveying pipe.

Q3:What are the applications of your RTP composite pipe?

Steel skeleton reinforced RTP composite pipe:

This pipe is suitable for the transportation and mixed transportation of oil, gas and sewage in the petroleum and gas industries. It is also suitable for the transportation of drinking water, fire water and corrosive liquids.

Flexible composite high-pressure conveying pipe:

Composite pipes suitable for oil and gas gathering and transportation, high-pressure alcohol injection, oil field water injection, sewage treatment, etc. Main uses: single well gathering and transportation pipeline network in onshore oil and gas fields; high-pressure alcohol injection pipelines for gas production; oil field water injection pipelines; sewage transportation pipelines; oil, gas and water mixed transportation pipelines in acidic oil and gas fields; underground continuous water injection pipelines; brine, chemical raw materials and other corrosive medium transportation pipelines

Q4. Can you provide samples?

Yes, samples are available. For normal products, samples are free, you just need to bear the freight; for those high value products, you need to pay the freight and certain product cost. After we cooperate for some times or when you are our VIP customers, free sample will be offered when you need.

Q5. What's your delivery time?

For small quantity products, they will delivered to you by international courier(DHL,FedEx, USP ect.) or by air. Usually it will cost 3-5days that you can get the goods after delivered. For large quantity products, delivered by sea. It will cost days to weeks to come to your destination port, which depends on where is the port.

Q6. What is your payment term?

L/C, T/T, Western Union.

Q7. What is your price term?

The price is base on FOB, CFR or CIF.

Q8. Quality control, warranty and guarantee

We control the quality of raw material. We only work with stated enterprise and their quality is stable; Our workers have rich experience, our production machinery is advanced; Before packaging, we make very strictly test and inspection by QC.

We need to know following information to give you our best quotation for the hose:

1.Size range(ID,OD)

2.What's the material of composite hose ? PE, PP, PA or others?

3.Transport medium, petroleum and gas, industry oil or others?

4.What's the production standard of RPT composite hose? GB/T, ISO or others?

5.Working pressure

6.Working temperature

7.Do you need fittings? If you need, pls send us the drawing and material of fittings

8.Overall length

9.Quantity